Comprehensive Guide to Thermistor Sensor Manufacturing

Aug 16, 2024"Welcome to the Focusens website. If you reply to the news, please wear it online and prepare for help."

Incoming Material Inspection

To ensure that all raw materials meet product specifications and quality standards, our company inspects the batch number, production date, and quality certification documents of the materials. We conduct a visual inspection to ensure that there is no damage, contamination, or deformation.

It's important to note that we have standardized control procedures for supplier onboarding and material procurement, along with regular evaluations to enhance the quality assurance of both materials and supplier capabilities.

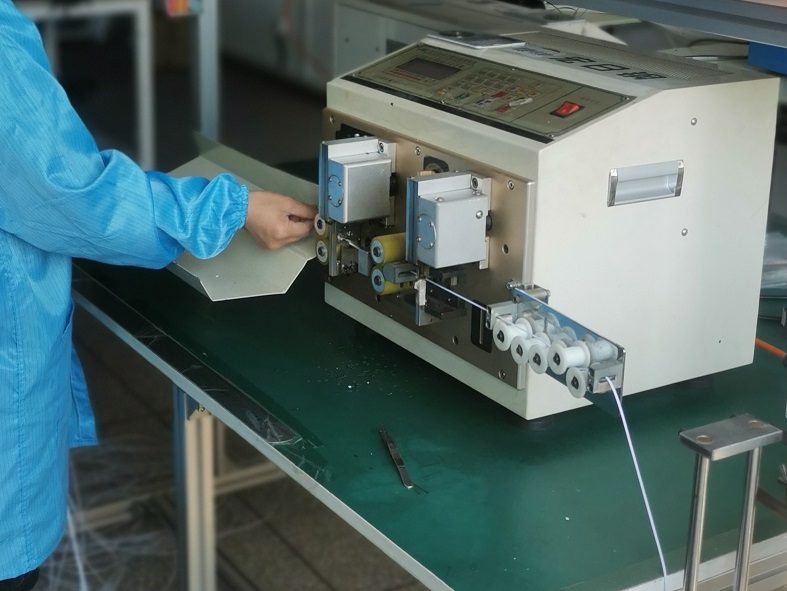

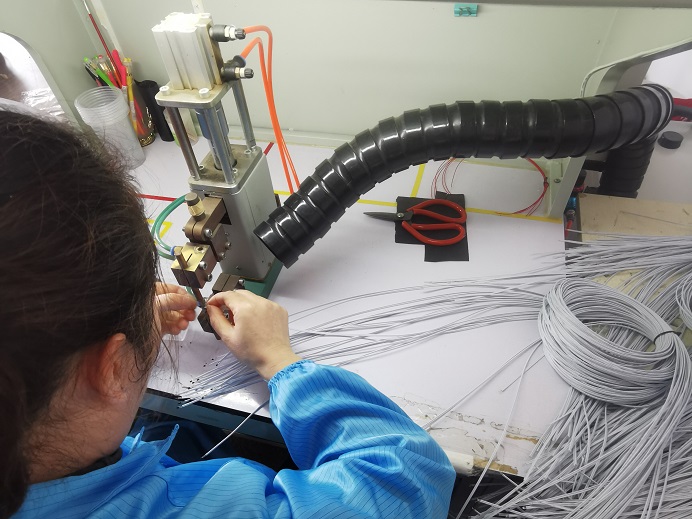

Cable Preparation (Cutting and Stripping Sensor Harness)

According to product design requirements, we cut the cables to the appropriate length. Using specialized cutting and stripping equipment and insulation strippers, we cut the cables based on design drawings. Additionally, to enhance signal conductivity and stability, and to improve downstream process performance, we perform tinning on the conductor of the stripped wires when the process requires it.

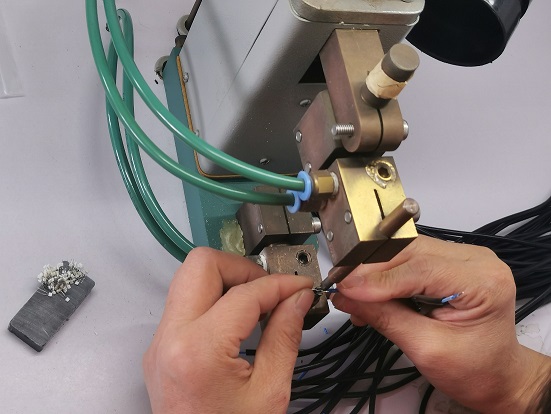

Connecting Components and Lead Wires (Spot Welding/Soldering/Copper Band Crimping)

Depending on the product's application and performance needs, we choose the appropriate connection method to securely connect the sensor's sensing elements with the wires. For example, when dealing with thermistors, which are temperature-sensitive resistors, it’s essential to ensure proper connections to maintain accurate temperature readings. Understanding what a thermistor does—primarily acting as a temperature sensor by changing resistance with temperature—helps guide these processes. We use spot welding equipment to connect the components. During soldering, we keep the soldering iron tip clean and control the welding time and temperature to ensure a secure connection without damaging the components.

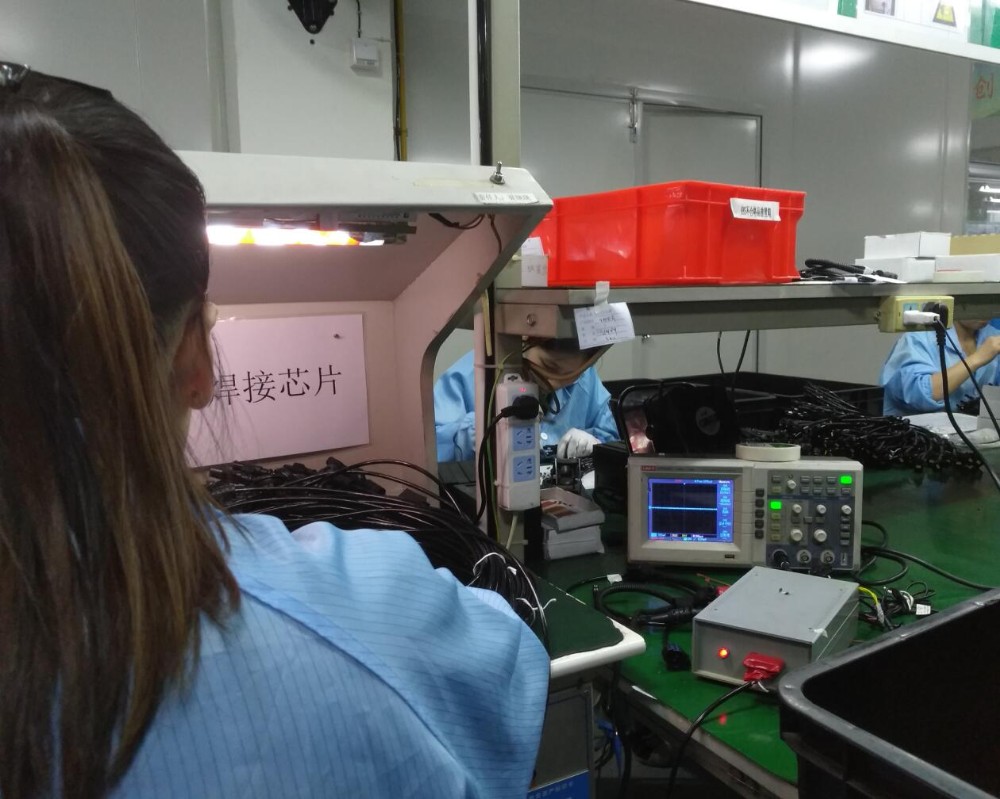

Weld Inspection

We inspect the weld points for completeness and uniformity using CCD, magnifying glasses, or visual inspection to ensure there are no cold solder joints, short circuits, or burrs. To ensure weld quality meets standards, weld inspection is treated as an independent process, with 100% of products inspected.

It is crucial to verify that connections, especially in thermistors, maintain their integrity to avoid false readings. If you’re wondering how to test a thermistor, it's important to measure its resistance at different temperatures to ensure it performs correctly.

Parts Taping and Alignment

To facilitate batch packaging operations, we align and tape the semi-finished sensors, ensuring that the final product's appearance and dimensions are consistent. This step is particularly important for thermistors, where precise alignment impacts their accuracy.

Encapsulation and Curing

Typically, our sensors undergo 2-3 encapsulation processes to ensure sufficient voltage resistance and insulation reliability for each sensor. This is vital for thermistors, as the encapsulation must protect the sensor from environmental factors without interfering with its ability to respond to temperature changes—central to what a thermistor does.

Adhesive Application and Housing Insertion

The sensor is placed into its housing, and a suitable amount of epoxy resin or other encapsulation material is applied to enhance stability. The sensor is carefully positioned within the housing. During the encapsulation process, we seal the pre-encapsulated product in the final housing, ensuring proper sealing, insulation, and moisture protection. Depending on the sensor's application requirements and working environment, we select appropriate encapsulation materials and techniques, which are crucial for the sensor's voltage resistance, waterproofing, shock resistance, and overall appearance. Approximately 80% of our products are encapsulated with epoxy resin, and we offer flexible solutions for high-temperature, high-humidity, high-voltage, and confined-space applications.

Adding Accessories (Sleeving, Color Codes, Serial Number Labels, etc.)

If customers or product specifications require it, some products are equipped with accessories such as sleeves, color codes, or serial number labels. We fully respect and meet customers' specific needs for personalized scenarios.

Final Product Inspection

To ensure the reliability of product performance, we conduct 100% testing on the following aspects. Each product undergoes at least three 300% inspection processes at our facility, with typical inspection items including: